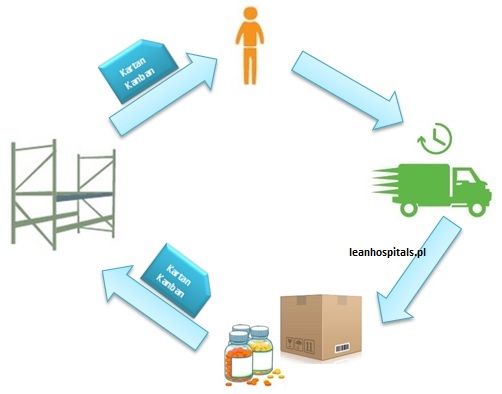

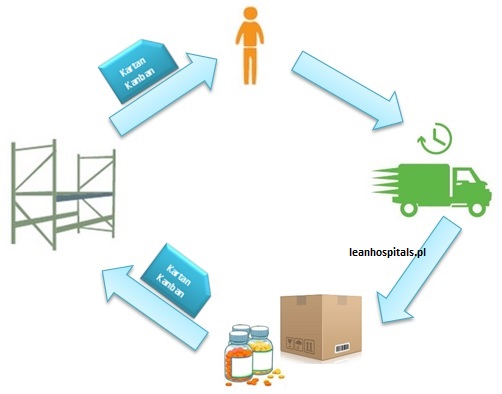

KANBAN system

Ordering stockroom supplies by use of KANBAN cards

It’s a simple stock logistics system and manufacturing management geared towards optimization of information flow and any kind of stock during a process. Basically, it refers to resource management in order to provide necessary quantities always on time, triggered by the KANBAN card and its appropriable indicator signal. When it comes to manufacturing, it was always considered one of the most popular tools to resource management. By minimizing stocking area it enables necessary resources to arrive on time according to formerly placed order. Kanban also bases on a crucial method called pull system. It means that demand of a product is raised in a practical moment with its precise quantity.

Speaking of management system, it’s completely new to the services area. No analogy to manufacturing makes it extraordinarily responsive towards specific branch. Most present in hospitals storerooms to provide dressings, disposable materials, medical equipment and medications. Under no circumstance should supplies reach their limit. The possible risk can even result in disruption of medical service. In other words, cause patients death or complications. In terms of medical branch, kanban system turns up to work outstandingly in storerooms equipped with disposable materials and medications.

How do we practice this approach?

Within an entirely organized stockroom each material has its assigned location, so called address. Material names are described on a wall, shelves and containers. Quantity is assessed according to current consumption. Minimum stock is crucial to regulate process performance and order supplies to have it received on time:

Due to specificity of medical service and its precariousness, process can turn out to be patchy, our safety stock can vary. Stock minimum can be visualised in various ways – red line on a wall, shelf or special container. Each resource is given a KANBAN card. If one can note minimum stock level indicator the kanban card should be collected and succeeded by placing an order.

Advantages:

- optimum quantity of supplies

- proper storage area management

- no outdated item

- simple visual management

- uninterrupted information flow

There are many advantages but the most important is the continuity of medical process. If stockroom always ensures minimum supplies the safety has its maximum level. All in all, safety of process and medical staff confidence are to reduce risk.